Electronic Test

When your thermal test requires focused controlled temperatures at the test area,

ThermalAir TA-5000 temperature cycling equipment can be used to test electronics operating temperature ranges from -90°C to +225°C. ThermalAir TA-5000 Series of Temperature Cycling Equipment and Temperature Shock Chambers of a variety of controlled temperature testing environments for bringing temperature to the parts and electronic components and assemblies requiring extensive reliability testing.

.

Temperature Testing from

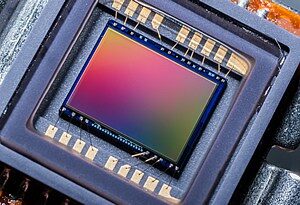

Accelerated Life Testing – Thermal Testing BGA Packages – Semiconductor Reliability Testing – IC Package Test – Semiconductor Testing – Semiconductor Testing

Electronic Thermal Test Equipment

MPI Thermal offers electronic test equipment and small thermal shock chambers that can thermal test any electronic, electromechanical, and non-electronic components at wide temperature ranges to meet your application requirements. We understand that electronic tests are the most extensive and longest running in your testing program and production line. We realize the critical importance of reliability and accuracy of electronic test equipment and thermal shock chambers. Our ThermalAir electronic temperature test systems are used at the test station, in the engineering lab and on the production test floor.

Factor Level Testing

The reliability of electronics assemblies is largely dependent on the quality of solder joints. Temperature Cycling is the most common reliability testing used in the electronics industry. Electronic assemblies subjected to temperature changes expand and due to the variability in materials and their coefficient of thermal expansion, localized stresses concentrate between components and substrates. Solder, as a joining material has to withstand these stresses for electronic components to provide and maintain mechanical and electrical function. Thus performance of solder joints has to be temperature tested at various rates because, mechanical properties of solders vary considerably with temperature changes.

Accelerated Life Testing – BGA Reliability Testing – Testing Operating Temperature of IC – Semiconductor Reliability Testing – Thermal Profiling – Semiconductor Reliability Testing

MPI Thermal thermal inducing equipment is portable and can easily be moved from one test station to another. Automotive Component manufacturers can use our ThermalAir TA-5000 system to quickly bring their parts to temperature right at the test location. Temperature cycling, thermal profiling and other environmental temperature conditioning is why MPI Thermal systems are part of the manufacturing temperature test process.

This is why the MPI Thermal TA-5000 Series of ThermalAir temperature products are part of the test.

Download the Datasheets

Semiconductor Reliability Testing – Accelerated Life Testing – Thermal Characterization – Semiconductor Testing – Semiconductor Reliability Testing – Semiconductor Reliability Testing

All types of electronic and non-electronic devices require temperature cycling and thermal shock test to make sure industrial products are unaffected by changes in beyond operating temperature ranges and harsh environmental stress conditions.

The ThermalAir TA-5000 Series can provide accurate temperature stimuli so the electronic component manufacturers can design, develop and produce highly reliable quality parts that meet the demanding standards of today’s electronic technologies.

The ThermalAir TA-5000 Series brings controlled temperature right to the test.

Reliability Test | Electronics Operating Temperature Range | Thermal Shock | Electronic Test Equipment | Electronic Temperature Test | Testing Operating Temperature Ranges

MPI Thermal ThermalAir Systems – developed by engineers and scientists with years of experience in Temperature Control, Software & Controller Design in Thermal Shock Test Systems.

When your thermal test requires focused localized temperatures at the test site, ThermalAir

TA-5000 temperature inducing equipment can be used to provide temperatures for a variety of environmental test applications.

Temperature cycling, thermal profiling, and other environmental temperature conditioning is why MPI Thermal systems are part of the manufacturing temperature test process.

Download the Datasheets

Thermal Shock Testing

Thermal shock testing is typically performed to predict the ability of parts and components to withstand sudden temperature changes. ThermalAir systems are used in a variety of industrial electronic test applications. Thermal cycling, temperature characterization, and thermal shock testing of parts & electronics in industries such as automotive, telecom, aerospace, medical, sensors, RF microwave and other related electronic temperature test applications, is what the ThermalAir TA-5000 provides for in multiple industry market segments.

Download the Datasheets

Thermal Cycling BGA – BGA Reliability Testing – Thermal Cycling – Semiconductor Reliability Testing – Accelerated Life Testing CSP – Testing Operating Temperature of ICs

ThermalAir TA-5000A with Small Thermal Shock Test Chamber

- ThermalAir TA-5000A shown connected to a small temperature shock chamber

- Our temperature shock chambers can be customized to fit user test application

- ThermalAir thermal test chambers connect Direct or via Flex Transfer Hose

- Fastest temperature ramp rates without the use of LN2 or CO2

- Portable enough to easily moved between workstations or testers

Bring temperature testing directly to your test location for industrial electronics and non-electronics components. Temperature Cycling Test capabilties from temperatures from -100°C to +225°C

Products Overview

ThermalAir Thermal Test

Systems for Electronics

The design challenges go well beyond simply delivering processing power and high-speed data transfer. Design engineers must also safely manage heat generated by those processes in the confines of tight vehicle packaging requirements, as well as ambient and cold temperature fluctuations, while adhering to stringent safety and reliability standards of the electronics industry.

Environmental Stress Testing

Environmental stress conditions such as radiation exposure, temperature extremes, vibration, and dirt encountered by the military, on factory floors, and under the hoods of automobiles, these semiconductor devices need to keep working. To assure quality and reliability of electronic devices, semiconductor manufacturers need to simulate harsh environments during the engineering and production test stage. This is why the MPI Thermal TA-5000 Series ThermalAir temperature test products are part of the test.

Temperature Cycle Test – Temperature Forcing Electronics – Temperature Test Electronics – Temperature Forcing Systems – Temperature Inducing Electronics

ThermalAir Thermal Test

Systems for Electronics

The design challenges go well beyond simply delivering processing power and high-speed data transfer. Design engineers must also safely manage heat generated by those processes in the confines of tight vehicle packaging requirements, as well as ambient and cold temperature fluctuations, while adhering to stringent safety and reliability standards of the electronics industry.

Environmental Stress Testing

Environmental stress conditions such as radiation exposure, temperature extremes, vibration, and dirt encountered by the military, on factory floors, and under the hoods of automobiles, these semiconductor devices need to keep working. To assure quality and reliability of electronic devices, semiconductor manufacturers need to simulate harsh environments during the engineering and production test stage. This is why the MPI Thermal TA-5000 Series ThermalAir temperature test products are part of the test.

Temperature Forcing Systems – Temperature Forcing Electronics – Temperature Testing Electronics – Temperature Cycling Test – Temperature Test Electronics

Thermal Cycle PCB’s, Componets, and Parts

The ThermalAir TA-5000 Series can provide accurate temperature stimuli so the electronic component manufacturers can design, develop and produce highly reliable quality parts that meet the demanding standards of today’s electronic technologies.

All types of electronic and non-electronic devices require temperature cycling and thermal shock test to make sure industrial products are unaffected by changes in temperature and other harsh environmental stress conditions.

Temperature Forcing System

MPI ThermalAir temperature forcing systems provide a direct thermal stream of clean dry hot and cold air directly to the part that needs to be thermal tested. In the lab or on the production floor, ThermalAir Series provide unparalleled thermal stress testing capabilities for scientist and engineers.

The ThermalAir system allows you to generate very precise controlled temperature for simulation test in Thermal Shock, Temperature Conditioning, Stress Screening, Temperature Cycling and more. Thermal test processes can be accomplished with our ThermalAir system. Ramp, Cycle, Dwell and Soak times are fully programmable with a touch of a button.